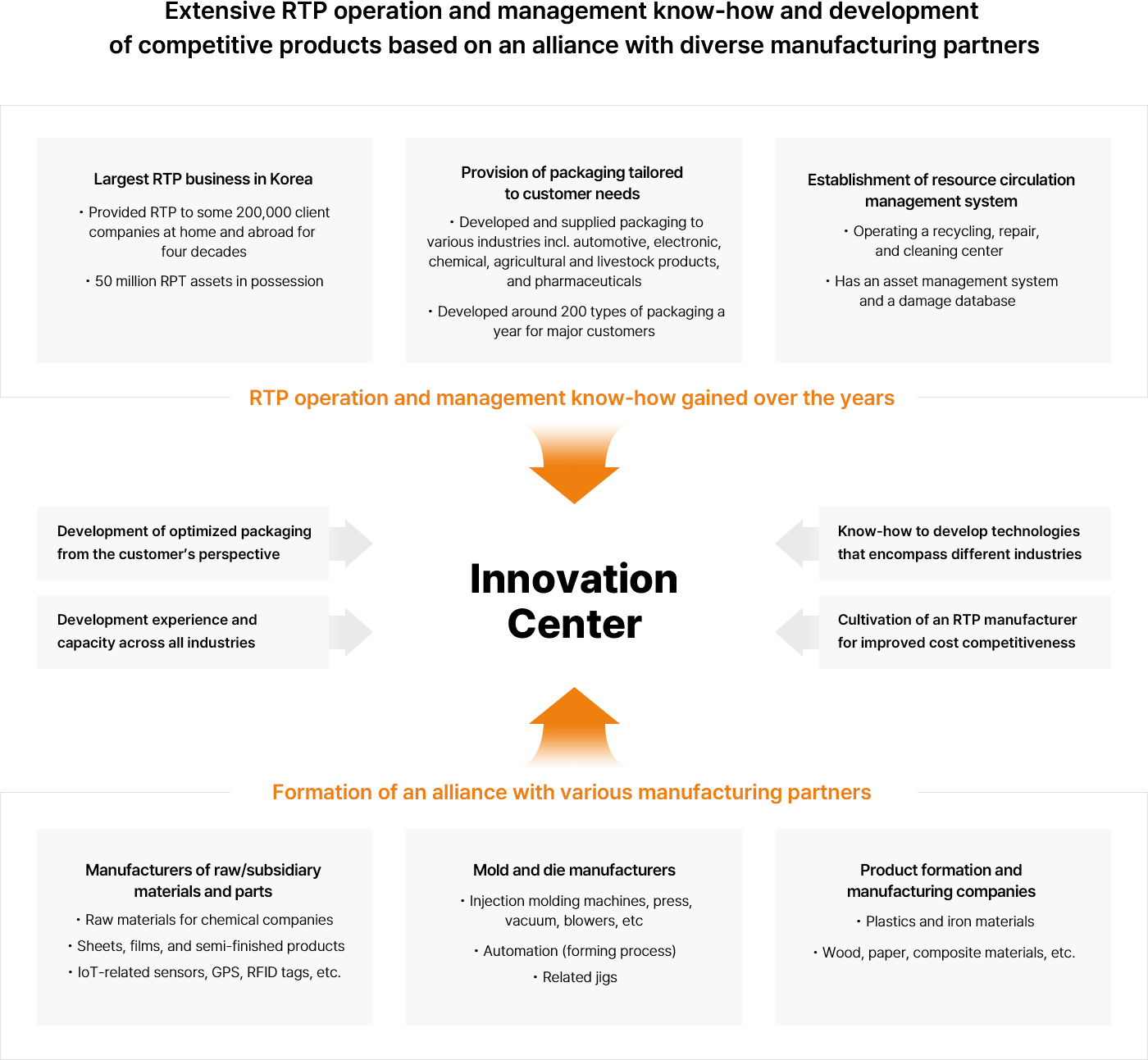

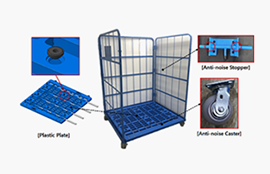

LogisAll Institute of Technology is dedicated to providing comprehensive solutions

by promptly and accurately responding to various customer demands and

developing products that are suitable for their purposes.

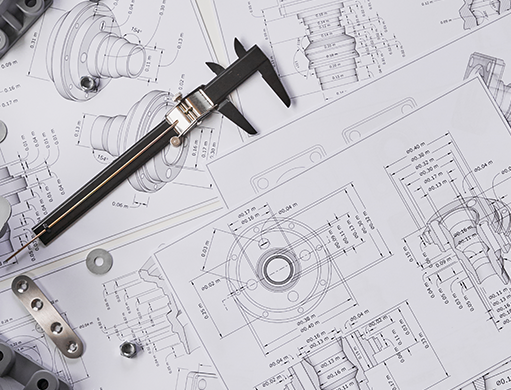

Based on top-class packaging technology, LogisAll Institute of Technology continuously conducts research and development and ensures product quality management to enhance reliability and expand achievements across various industries. By analyzing the strength of the developed products, potential issues that may arise after production can be addressed in advance, and the developed products are verified through strength tests such as compression, impact, and vibration.