Auction Platform for Used Forklifts - Logismart Auction

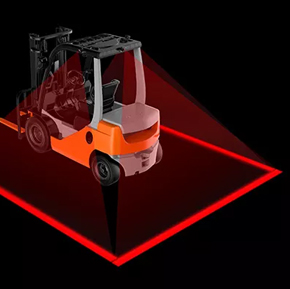

Online platform for auctioning used forklifts, providing easy search and transaction of used forklifts through online auctions, the first online auction in Korea

-

- Online Auction

- An online platform that allows easy searching and trading of used forklifts through transparent and fair real-time bidding in 'seconds' without the need for on-site visits

-

- Consumer-Centric Auction

- A reverse auction solution where consumers have the leading role in determining the price, ensuring competitive pricing, and improving transaction success rates through strong membership recruitment based on strong needs

-

- Quality Certification of Products in Sale

- Posting of used forklift listings that have undergone 13 essential inspections by professional engineers on the auction site

-

- Mobile Service Support

- Participation in real-time auctions, made easy and convenient anytime, anywhere through a mobile application