The Integrated Collaborative Logistics System is an operational approach that combines and provides a unified system for simplifying and standardizing logistics equipment, shared utilization system, JIT system, logistics quality assurance, and logistics information system.

-

- 01. Simplification and Standardization of Logistics Containers

- Development and integrated operation of standardized logistics containers between lines

Line-to-Line designpackaging standardization -

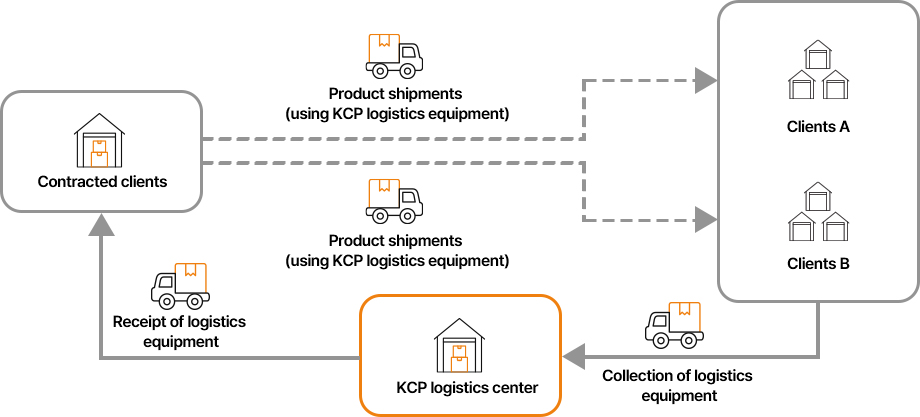

- 02. Pooling System Operation

- Minimization of logistics costs through shared use of logistics infrastructure

Transportation vehiclesLogistics containersLogistics personnel -

- 03. JIT System Operation

- Optimal scheduling of dispatches aligned with product production schedules

On-timePrecise

quantity -

- 04. Logistics Quality Assurance

- Zero-defect transportation of materials between production lines

Material Production LinesProduct Production Lines -

- 05. Logistics Information System

- Realization of SCM visibility, including supply chain / inventory / and metrics

Control CenterInformation Devices